Automotive Cable Solutions

Built for the Road, Engineered for Endurance

At GG Group, we are at the forefront of the automotive revolution, delivering high-performance cables and wiring systems that power the vehicles of today and tomorrow. As a global, family-owned enterprise with over 80 years of expertise, we specialize in technologically advanced solutions for energy and data transmission, tailored to the automotive industry’s most demanding applications. From electric vehicles (EVs) to autonomous driving systems and advanced driver-assistance systems (ADAS), our cables are designed to drive progress with precision, reliability, and innovation.

Global Expertise

Rooted in our Austrian heritage and now operating across 13 locations on three continents, GG Group combines a legacy of craftsmanship with a forward-thinking approach. Our mission is to provide automakers with custom-engineered solutions that meet the evolving needs of e-mobility, digitalization, and sustainability, ensuring vehicles perform at their best in any environment.

When it comes to automotive cables, GG Group sets the standard for excellence. Here’s why leading global automakers and tier-one suppliers trust us to power their innovations:

- Bespoke Engineering: We design and manufacture high-voltage (HV) and low-voltage (LV) cables using copper and aluminum. Our cables are available in shielded and unshielded configurations, with cross-sections up to 240 mm² and beyond, providing exceptional versatility. Whether you need flexible battery cables for dynamic applications or form-stable wiring for compact vehicle architectures, our solutions are tailored to your exact specifications.

- Pioneering Innovation Through Collaboration: Our research and development (R&D) teams work closely with automakers, contact system manufacturers, and industry partners to co-develop cutting-edge solutions. From space-optimized flat or round cable designs to specialized stranded constructions, we anticipate future needs and deliver products that push the boundaries of automotive technology. Our open innovation approach fosters collaboration with universities, research institutions, and suppliers, ensuring we stay ahead of industry trends.

- Uncompromising Quality and Reliability: Quality is non-negotiable at GG Group. Our state-of-the-art testing and validation facilities, including advanced laboratories for physical, chemical, and electrical analysis, ensure every cable meets the highest industry standards. We hold certifications such as IATF 16949, ISO 9001, ISO 14001, ISO 45001, and ISO 50001 across our global sites, reflecting our commitment to quality, environmental responsibility, and workplace safety. Our rigorous testing processes—covering everything from material properties to radio-frequency performance—guarantee durability and performance under the toughest conditions.

- Mastery of Specialized Manufacturing: With decades of experience in automation, industrialization, and specialized processes, we excel in complex manufacturing techniques. For aluminum cables, we employ advanced methods like plasma soldering and resistance welding to enhance conductivity, vibration resistance, and longevity. For copper cables, we leverage all standard contact technologies, ensuring seamless integration with automotive systems. Our in-house cable production and cable set assembly create valuable synergies, enabling us to deliver end-to-end solutions with unmatched efficiency.

- Sustainability as a Core Value: As a family-owned business, we are committed to sustainable practices that support a greener automotive future. Our Integrated Management System (IMS) aligns with ISO 14001 for environmental management, ISO 45001 for occupational health and safety, and ISO 50001 for energy efficiency. By optimizing processes and materials, we reduce our environmental footprint while delivering products that support the shift to electric and low-emission vehicles.

- Global Reach, Local Expertise: With production facilities in Austria, Mexico, China, the Czech Republic, the Republic of Moldova, and beyond, we combine global scalability with localized support. Our Regional Customer Service Center in Shanghai strengthens our ability to serve the APAC region with tailored design and development for automotive cable harnesses and components. Wherever you are, GG Group is your trusted partner.

Let’s power the future together. Contact our specialists today to explore how our automotive cables can accelerate your vision.

Critical Applications for Automotive Excellence

Our cables are the backbone of the automotive systems that define modern mobility. Engineered for performance, safety, and efficiency, they power a wide range of applications:

- High-Volt Battery Connections: Our HV cables ensure seamless energy transfer between EV batteries and power systems, supporting the rapid growth of electric mobility. Designed for high-capacity and reliability, they handle the demands of next-generation battery systems with ease.

- EV Charging Systems: We produce HV charging cables in copper or aluminum, optimized for fast, safe, and efficient charging. Available in shielded or unshielded designs, our cables meet the rigorous requirements of public and private charging infrastructure, ensuring compatibility and durability.

- Electric Motor to Inverter Wiring: Our precision-engineered cables deliver efficient power transfer between electric motors and inverters, enabling smooth and responsive drivetrain performance. These solutions are critical for the performance and efficiency of electric and hybrid vehicles.

- Auxiliary HV Consumers: From climate control systems to ADAS and infotainment, our versatile HV cables power additional high-voltage components, enhancing vehicle functionality and passenger comfort.

- Battery Cable Sets (LV/48V): Our LV cable sets, available in flexible or form-stable designs, provide reliable connections for battery-to-distributor, potential equalizer, or power distribution systems. Copper braided or insulated cables offer exceptional flexibility and vibration resistance, making them ideal for high-stress environments.

- Potential Equalizer and Grounding Systems: Our copper-based grounding and potential equalizer cables, available as insulated wires or braided designs, ensure electrical safety and stability, particularly in high-vibration applications.

Ethernet cables for data transmission rates of over 10 Gbit/s (frequency rate up to 9 GHz) are used to connect various control devices, sensor units, and multimedia units.

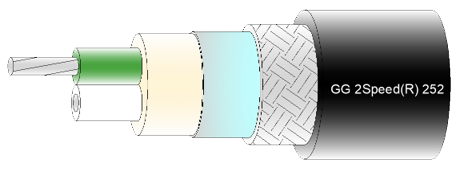

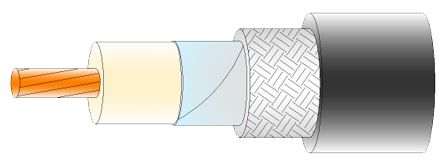

Coaxial cables reaching up to 20 GHz that are conventionally used for analog signals, but also for new applications, e.g. digital signals (digital radio, infotainment, GPS, WiGig) and camera signals.

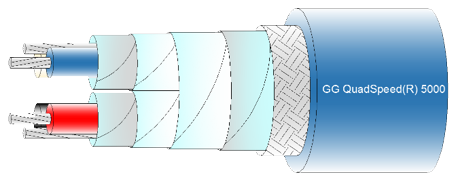

HSD cables are used for digital data transmission (data volumes up to 12 Gbit/s at frequencies of up to 7 GHz), such as side-, front- und rear view cameras, back seat displays, hires centre displays, automotive infotainment systems.