Cables & Wires for Plant Engineering

Built for Production, Engineered for Growth

In modern industrial facilities, every connection is a critical link in your production chain. GG Group's plant engineering cables have the dependability, flexibility and technical excellence today's manufacturing plants demand.

Dependability that fuels production

In the demanding world of industrial manufacturing, there is no such thing as a small production line interruption. Downtime is costly. This means that your facility's cable infrastructure must perform flawlessly under the most demanding conditions and on endless schedules.

Our plant engineering cables have the industrial durability and engineering that will perform as intended year after year. Our cables have a reinforced structure which prevents damage from mechanical stress, vibration, and constant motion to ensure non-stop operation for your critical systems. When the production line depends on perfect electrical integrity, GG Group will provide connections that you can trust entirely. Our cables provide consistent performance for routine operations and at peak production periods. With GG Group, you are investing in production continuity and ongoing operations.

Cables Engineered for Industrial Environments

Manufacturing facilities offer some of the most hostile environments for electrical components. Our cables are engineered to perform in positions that an off-the-shelf cable would fail in a short time. Our advanced formulations provide superior resistance to the industrial chemicals, lubricants, and cleaning agents commonly found in manufacturing environments. With operating temperature ranges from -40°C to +90°C, our cables maintain perfect performance in everything from refrigerated processing areas to heat-intensive production zones. Special cables can also be operated at temperatures over 200°C.

In areas of constant machine movement, our highly flexible cables offer exceptional bend radius and abrasion resistance for performance that prevent premature wear. Whether facing corrosive atmospheres, moisture exposure, or mechanical stress, GG Group cables maintain their integrity and functionality, providing the protection your critical systems need.

Contact our specialists today to discuss how GG Group's cable solutions can enhance the reliability, efficiency, and performance of your plant and manufacturing operations.

Ready for Industry 4.0

Today's manufacturing facilities are connected, automated, and data-driven. GG Group's cables are designed to support the sophisticated requirements of modern industrial technology.

Our industrial data cables provide the high-speed transmission capabilities needed for real-time monitoring and control systems, with advanced shielding that maintains signal integrity even in electromagnetically challenging environments. With support for industrial Ethernet (10 Base-T1S und 10 Base-T1L), Fieldbus and PROFINET systems, and specialized control protocols, our solutions enable the seamless flow of information that powers smart manufacturing.

As factories become more integrated and intelligent, our hybrid cables combine power, control, and data transmission in single, space-efficient solutions that simplify installation and enhance reliability. By choosing GG Group for your connectivity needs, you're building the foundation for manufacturing innovation and digital transformation.

Globally Certified

In today's global manufacturing landscape, manufacturers need to consider all regional and global standards for product specifications. GG Group cables certification portfolio will ensure your facility will meet requirements around the globe.

Our cables carry all major international approvals including VDE, UL and CSA enabling seamless implementation in facilities across global markets. With careful attention to safety regulations and performance standards, we deliver cables that satisfy even the most stringent compliance requirements.

For specialized environments with unique certification needs—from food processing to pharmaceutical manufacturing – our solutions meet industry-specific standards while maintaining the exceptional performance you expect. When regulatory compliance is as important as operational performance, GG Group delivers complete peace of mind.

Solutions for Every Application

Modern industrial facilities encompass a diverse range of equipment and systems, each with unique connection requirements. GG Group's comprehensive portfolio addresses this complexity with specialized solutions for every application.

For machine tools and production equipment, our control and connection cables provide reliable signal transmission with superior flexibility and mechanical durability. In conveyor and material handling systems, our power and motor cables deliver consistent performance despite constant movement and vibration. For critical energy control and distribution systems, our special high-power cables provide the safety and reliability demanded in industrial settings. Our range of single core FEP and EFTE cables (extending the temperature range up to 200°C) in various sizes offers flexible solutions for different power requirements across your facility.

From robotic welding cells with extreme heat exposure to food processing areas with stringent hygiene requirements, we offer application-specific cables designed for the exact conditions they'll face. Our industrial data cables provide the high-speed transmission capabilities needed for real-time monitoring and control systems, with advanced shielding that maintains signal integrity even in electromagnetically challenging environments. With support for industrial Ethernet including PROFINET, Fieldbus systems, and specialized control protocols, our solutions enable the seamless flow of information that powers smart manufacturing. These sensor and data cables can be seamlessly integrated into industrial plant construction applications to ensure reliable communication throughout your manufacturing processes.

Whatever your manufacturing specialty—automotive, electronics, food and beverage, pharmaceuticals, or general industrial production—GG Group provides the exact cable solutions your facility requires.

Custom Engineering Support

We recognize that standard products don't always address the unique challenges of specialized manufacturing environments. GG Group's engineering team works directly with you to develop custom cable solutions perfectly matched to your specific requirements. Our consultation process begins with a thorough analysis of your application, including environmental factors, mechanical demands, electrical specifications, and performance requirements. Drawing on decades of cable engineering expertise, we then design solutions that optimize performance for your particular needs.

With manufacturing capabilities that include specialized jacketing compounds, unique conductor configurations, and custom shielding systems, we deliver precisely the performance characteristics your facility demands. From concept through installation and beyond, our technical team provides support that ensures perfect integration with your industrial systems.

Complete System Solutions

Beyond individual cables, GG Group offers complete connectivity systems that streamline installation and enhance reliability throughout your facility. For dynamic applications, our engineered drag chain assemblies provide turnkey solutions that ensure perfect performance in constant-motion environments. Our modular approach to industrial connectivity allows for standardized interfaces and simplified maintenance, enhancing your facility's long-term operational efficiency.

When you partner with GG Group, you're getting more than just cables—you're getting integrated solutions designed for the complex realities of modern industrial environments.

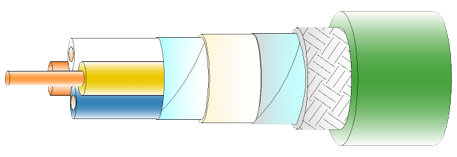

- Data transmission

- Robust application in robotic or process applications connecting different robotic station with each other (static)

- External interconnection or internal wiring

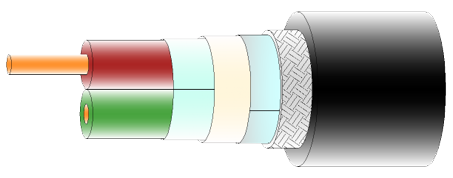

- Data transmission

- Robust application in different plant or process applications

- External interconnection or internal wiring

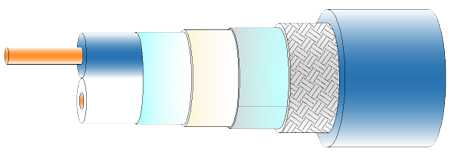

- Data transmission

- Robust application in different plant or process applications

- External interconnection or internal wiring

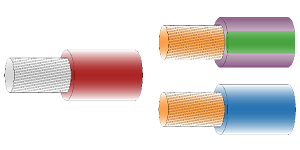

- High temperature applications like wielding

- High reliable application: secured networks or power supplies

- critical energy control and distribution systems

- Use inside and outside of machines

- Use in power control cabinets