Automation & Robotics Cable Solutions

Built for Precision, Engineered for Intelligence

In today's automated manufacturing environment, cable failure isn't just an inconvenience—it's production paralysis. GG Group's specialized automation and robotics cables deliver the reliability, precision, and durability that keep your advanced systems performing flawlessly.

Maximizing Uptime

In modern manufacturing, every minute of unexpected downtime translates directly to lost revenue. Your automation infrastructure needs cables that won't just perform - they'll perform relentlessly.

Our automation and robotics cables are engineered with manufacturing realities in mind, delivering exceptional reliability in 24/7 production environments. With reinforced construction that stands up to continuous operation and material science that prevents premature aging, our cables ensure your automated systems maintain perfect functionality year after year.

When your production targets depend on flawless equipment performance, GG Group delivers the electrical infrastructure that keeps your facility running at maximum efficiency. By investing in our high-performance cable solutions, you're investing directly in production continuity and operational excellence.

Engineered for Constant Motion

The dynamic nature of industrial automation creates unique challenges for cable systems. From rapid robotic movements to constant flexing in drag chains, our cables are designed specifically for applications where motion never stops.

Our robotics cables deliver industry-leading torsional performance, withstanding millions of twisting cycles without degradation. With specialized construction that maintains perfect electrical integrity through continuous bending, flexing, and acceleration, our cables remain reliable long after conventional solutions would fail.

For high-speed applications, our advanced jacketing compounds provide exceptional abrasion resistance that prevents wear even in constant-contact environments. Whether facing rapid direction changes, complex three-dimensional movements, or repetitive cycling, GG Group cables maintain their performance characteristics throughout their extended service life.

Contact our automation specialists today to discuss how GG Group's cable solutions can enhance the reliability, precision, and efficiency of your automation and robotics systems.

Resistant to Industrial Environments

Manufacturing facilities present some of the most challenging environments for electrical components. Our automation cables are specifically designed to withstand the harsh realities of industrial production.

With advanced formulations that resist cutting oils, coolants, and industrial cleaning agents, our cables maintain their integrity despite constant chemical exposure. For specialized environments, our welding-resistant cables provide protection against spatter and extreme heat in robotic welding cells.

From the freezing temperatures of food processing to the heat of foundry operations, our cables perform consistently across temperature ranges from -40°C to +105°C. With resistance to dust, moisture, and mechanical stress, GG Group cables deliver reliability that conventional solutions simply can't match.

Data Integrity in Noisy Environments

Modern automation systems depend on perfect signal transmission for precise control and monitoring. Our cables ensure flawless data integrity even in the most challenging electromagnetic environments.

With advanced shielding technology that blocks external interference, our control and data cables maintain signal purity despite proximity to motors, drives, and power systems. GG offers a wide portfolio of Industrial data and bus cables supporting protocols including EtherCAT, PROFINET, ProfiBUS, CAN BUS, and EtherNet/IP with perfect signal integrity, enabling the real-time control and monitoring essential to advanced manufacturing. Our specialized solutions also support proprietary protocols for camera and display control applications.

From low-level sensor signals to high-speed data networks, our cables provide the consistent performance that keeps your automation systems communicating flawlessly. All data and bus cables are available for different applications including drag chain, robotic, or torsion bending to meet your specific installation requirements. When milliseconds matter in your control systems, GG Group delivers connections you can trust completely.

Specialized for Every Automation Application

Modern manufacturing encompasses a diverse range of automation technologies, each with unique connection requirements. GG Group's comprehensive portfolio addresses this complexity with specialized solutions for every application.

For servo motors and precision drives, our power and feedback cables provide the perfect combination of flexibility and electrical performance, ensuring precise motion control in demanding applications. Our encoder and resolver cables deliver the signal integrity essential for position feedback, maintaining accuracy even in high-interference environments.

From traditional PLCs to advanced industrial control systems, our control and signal cables provide reliable connections that ensure perfect system integration. For robotic applications, our specialized cables withstand the complex stresses of multi-axis movement while fulfilling all electrical requirements.

Whether you're operating collaborative robots, high-speed production lines, or advanced process control systems, GG Group provides the exact cable solutions your automation infrastructure requires.

Ready for Industry 4.0

As manufacturing becomes increasingly digital and interconnected, your cable infrastructure must support the demands of smart factory initiatives. GG Group's solutions are designed for the future of industrial automation.

Our industrial network cables provide the high-speed connectivity essential for IoT implementations, with performance characteristics that support the massive data requirements of connected manufacturing. With specialized constructions that combine power, control, and data functions, our hybrid cables simplify installation while enhancing reliability in Industry 4.0 environments.

Data and bus cables are becoming increasingly critical for industrial automation with the rise of AI and Industry 4.0 applications. GG Group is actively supporting the development of new technologies like Single Pair Ethernet (SPE), making cabling infrastructure even more efficient while maintaining the highest reliability standards for managing entire automation lines.

From edge computing to cloud connectivity, our solutions support the seamless flow of information that powers predictive maintenance, quality monitoring, and production optimization. By choosing GG Group for your connectivity needs, you're building the foundation for manufacturing innovation and digital transformation.

Proven Through Rigorous Testing

When your production depends on cable reliability, GG Group's comprehensive testing provides the assurance you need.

Our specialized testing facilities simulate the demands of real-world automation environments. Through accelerated aging, chemical exposure, and temperature cycling, we validate durability that exceeds your operational requirements.

Every product undergoes comprehensive electrical testing to ensure signal integrity and consistent performance characteristics. Our cables meet stringent national and international certifications, including UL standards, giving you complete confidence in their safety and compliance. With documented quality control at every stage of manufacturing, you can install our cables with complete confidence in their long-term reliability.

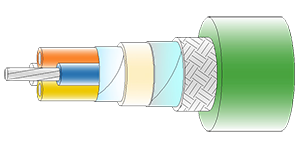

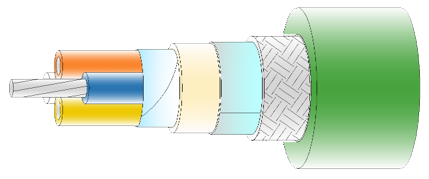

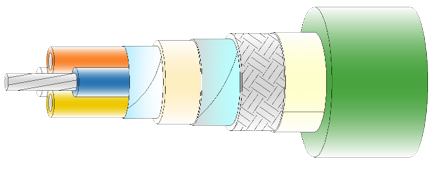

The manufacturer-independent PROFINET standard enables transmission rates of up to 100 Mbps. The special feature is the consistent use of a uniform conductor cross-section AWG22, regardless of whether for fixed installation (type A) or limited flexible use (type B) indoors. The cables for use in control cabinets (Cabinet Cable) are an exception.

Data transmission

Robust application in different robotic applications (flexible)

Torsion resistant (10,000 cycles)

Data transmission

Robust application in different robotic applications (high dynamic)

Highly drag chain resistant (10 MIO cycles)

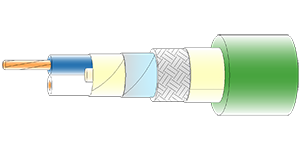

Internal wiring of electronic equipment and appliances

Single Pair Ethernet cables extend the existing Ethernet infrastructure with a further cabling option. By reducing the dimensions and consequently the weight, SPE Ethernet is finding its way into the sensor-actuator level for the first time and will replace conventional BUS systems with the extended intelligent possibilities of the Ethernet standard in the long term.