High-Performance Data Cables by GG Group

Built for Transmission, Engineered for Evolution

In a world driven by data, GG Group stands as a global leader in crafting high-performance data cables that fuel connectivity across the automotive and industrial sectors. As a family-owned enterprise with over 80 years of expertise, we specialize in technologically advanced wiring systems for seamless, secure, and high-speed data transmission. From enabling autonomous driving to powering smart industrial networks, our data cables are engineered to meet the rigorous demands of today’s interconnected systems with exceptional reliability and innovation.

Why GG Group Data Cables Excel

At GG Group, we don’t just manufacture cables—we deliver solutions that connect the future. Here’s why industry leaders trust our data cables to power their most advanced applications:

- Precision-Engineered for High-Speed Connectivity: Our data cables are designed to support the high-bandwidth, low-latency requirements of cutting-edge technologies. Whether it’s advanced driver-assistance systems (ADAS) or industrial IoT, our cables ensure flawless data transfer, even in the most demanding environments.

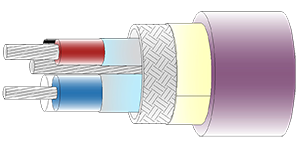

- Customized for Your Needs: We work closely with automakers, industrial clients, and technology partners to develop bespoke cable solutions. From shielded twisted-pair designs to high-frequency cables, we tailor every aspect—material, shielding, and construction—to optimize performance and integration.

- Uncompromising Quality Standards: Quality is the cornerstone of our operations. Our state-of-the-art testing laboratories use advanced techniques like spectroscopy, chromatography, and radio-frequency testing to validate signal integrity and durability. Certifications such as IATF 16949, ISO 9001, ISO 14001, and ISO 45001 across our global facilities underscore our commitment to excellence. We actively participate in development of standards such as ISO, IEEE, ASA and OpenAlliance.

- Advanced Manufacturing Expertise: With decades of experience in automation and specialized processes, we produce data cables that withstand vibration, temperature extremes, and electromagnetic interference. Our in-house production of cables and cable sets ensures synergy, enabling us to deliver robust, high-performance solutions with precision.

- Sustainability at Heart: As a family-owned business, we prioritize sustainable practices. Our Integrated Management System (IMS) aligns with ISO 14001 for environmental responsibility and ISO 50001 for energy efficiency, ensuring our data cables support a greener, more connected future.

Contact GG Group today to find out how our data cable solutions can take you to the next level.

Key Applications for Seamless Connectivity

Our data cables are the backbone of mission-critical systems, delivering reliable performance across diverse applications:

- Automotive Data Networks: Power the future of mobility with cables designed for ADAS, infotainment, and vehicle-to-everything (V2X) communication. Our high-bandwidth cables support real-time data transfer for autonomous driving, ensuring safety and responsiveness.

- Industrial IoT and Automation: Enable smart factories with data cables that facilitate real-time monitoring, control, and automation. Our solutions support high-speed data exchange in complex industrial networks, driving efficiency and innovation.

- Custom Connectivity Solutions: From high-frequency coaxial cables to shielded twisted-pair designs, we offer a wide range of data cables tailored to specific requirements. Whether it’s minimizing signal loss or enhancing electromagnetic compatibility, our cables deliver.

- Telematics and Sensor Systems: Our cables connect sensors, cameras, and control units, ensuring reliable data flow for advanced vehicle and industrial applications.

Driving Innovation

Innovation is at the core of GG Group. Our modern innovation management system transforms creative ideas into market-leading solutions. Our advanced R&D and testing laboratories employ cutting-edge techniques to ensure our data cables meet the highest performance standards:

- Light and Electron Microscopy: For precise material analysis.

- Spectroscopy (UV/Vis, FTIR): To verify chemical composition.

- Radio-Frequency Testing: To ensure signal integrity and electromagnetic compatibility.

- Mechanical and Electrical Testing: To guarantee durability and performance under stress.

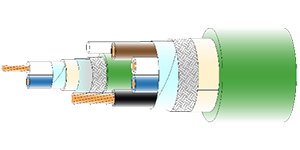

Our open innovation model fosters collaboration with external partners, including universities and suppliers, to advance high-speed connectivity, such as 5G-enabled Ethernet cables (e.g., Open Alliance TC-9) for vehicle-to-vehicle communication, autonomous systems, and Industry 4.0.

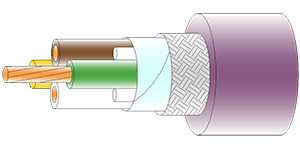

DeviceNet™ ist ein von Allen Bradley (Rockwell Automation) entwickeltes, auf bewährter CAN Technologie basierendes Bussystem.

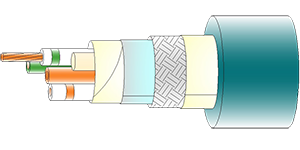

GG Group Industrial Ethernet cables are used in the field of industrial automation and are intended for fixed or conditionally flexible installation indoors.

Originally developed in the automotive sector, this bus system is very popular in the field of production automation and is standardized to ISO 11898.

Sensor or camera applications

Ethernet applications

Combined with power or control signals

M12 Type 2 highflex

Use inside and outside of machines

Connection between machine cells