Cable Solutions for Wind Energy

Built for the Skies, Engineered for Sustainability

When it comes to generating renewable energy, there is no room for failure from any connection in your wind power structure. GG Group's specialized wind energy cables and wires bring the reliability, durability, and technical precision needed to harness nature's most powerful resource.

Withstand the Extremes in Nature

Wind power installations face some of the harshest environmental conditions on the planet. From scorching sun to freezing storms, saltwater spray to constant vibration, our cables are engineered to thrive where others fail. Our advanced materials technology delivers exceptional resistance to UV radiation, ozone degradation, and temperature extremes from -40°C to +180°C. For offshore installations, our specialized cables offer superior protection against saltwater corrosion, while maintaining perfect electrical integrity year after year. Whether facing arctic conditions or desert heat, GG Group cables maintain consistent performance that keeps your wind farm producing at optimal capacity.

Engineered for Constant Movement

The nature of wind power presents its own set of unique challenges for electrical systems. With every rotation, adjustment, and directional change from the wind, there is a mechanical movement that is not considered in traditional cables. GG Group cables have been engineered to provide flexibility while maintaining electrical integrity with very tight radii of bending plus a supporting structure that allows for movement producing exceptional abrasion resistance. With our engineered designs and selected materials, we have created cables and wires that will perform excellently even after thousands and thousands of movement cycles!

Contact our specialists today to discuss how GG Group's solutions can enhance the reliability, efficiency, and longevity of your wind power installations.

Custom Solutions for Every Application

Wind energy infrastructure demands different cable specifications for each unique application. GG Group offers comprehensive solutions for every part of your wind power system.

For tower installations, our fixed-position cables provide the perfect balance of durability and performance, with fire-retardant and halogen-free construction that enhances safety throughout the structure. Within the nacelle, our flexible power and control cables deliver reliable connections to generators, motors, and monitoring systems. From rotor blade heating systems to lightning protection networks, our specialized cables are designed specifically for the unique demands of each component.

When it comes to connecting your wind farm to the grid, our medium-voltage interconnection cables ensure efficient power transmission with minimal losses.

Technical Excellence Without Compromise

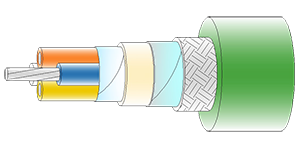

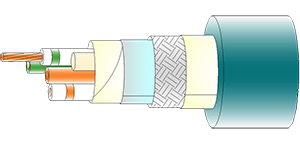

Behind every GG Group wind energy cable lies decades of engineering expertise and material science innovation. Our low and medium voltage offerings include both copper and aluminum conductor options, with electromagnetic compatibility (EMC) shielding that prevents signal interference even in complex electrical environments. Our highly flexible aluminum cables are specifically designed for lightweight applications in low voltage power transmission, such as connections between the wind mast and the base transformer station.

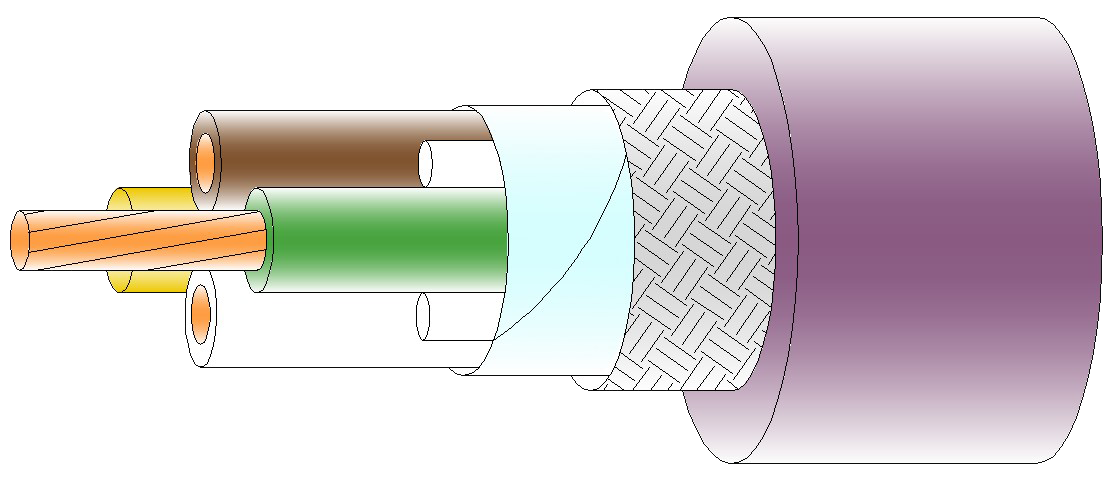

For critical control systems, our data transmission cables support high-speed communication with perfect signal integrity, ensuring flawless operation of your wind farm's monitoring and adjustment systems. GG Group’s comprehensive range includes specialized industrial ethernet and CAN bus cables that ensure reliable control and monitoring throughout your wind power installation. Fire-resistant construction meets the most stringent safety standards, while halogen-free materials protect both equipment and personnel in the event of emergency situations. Every cable is designed with optimal electrical performance characteristics to maximize efficiency and minimize energy loss throughout your wind power system.

Quality Verified

When your renewable energy investment depends on reliable connections, GG Group's testing protocols provide the assurance you need. Every product undergoes comprehensive testing for temperature cycling, water penetration resistance, UV stability, and mechanical durability. We validate our products against international standards including IEC requirements for wind energy applications, ensuring full compliance with industry specifications. With documented quality control at every stage of manufacturing, you can install our cables with complete confidence in their long-term performance, even in the most demanding wind power environments.

Customized to Your Specifications

Every wind power project presents unique challenges that demand specialized solutions. GG Group's engineering team works directly with you to develop cable systems perfectly matched to your specific requirements. Our "engineered to order" approach begins with consultation to understand the exact parameters of your installation, from environmental factors to mechanical demands and electrical specifications.

We then design custom cable solutions that optimize performance for your particular application, whether you're developing an innovative offshore floating platform or upgrading an existing onshore wind farm. From power cables to control cables or to specialized data transmission solutions, GG Group provides the complete spectrum of connectivity solutions needed for modern wind energy systems. Our manufacturing capabilities allow for specialized construction techniques, custom jacketing compounds, and unique conductor configurations that deliver precisely the performance characteristics your project demands. From concept to installation, our technical team provides support that ensures perfect integration with your wind power systems.

Powering the Renewable Energy Transition

At GG Group, we're proud of our role in advancing sustainable energy solutions. Our wind energy cables are more than just products – they're essential components in the global shift toward renewable power.

By delivering cable systems that maximize reliability and efficiency, we help make wind energy more economical and accessible. Our ongoing research and development focuses on innovations that reduce maintenance requirements, extend service life, and improve overall performance of wind energy installations. When you choose GG Group for your wind power cabling needs, you're partnering with a company that shares your commitment to clean energy and environmental stewardship. Together, we're building the infrastructure that will power a sustainable future.

The manufacturer-independent PROFINET standard enables transmission rates of up to 100 Mbps. The special feature is the consistent use of a uniform conductor cross-section AWG22, regardless of whether for fixed installation (type A) or limited flexible use (type B) indoors.

GG Group Industrial Ethernet cables are used in the field of industrial automation and are intended for fixed or conditionally flexible installation indoors.

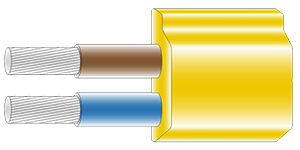

ASi cables, standardized in EN 50295 / IEC 62026, are used to connect devices at the lowest field level (sensors, actuators). Both data and power are transmitted via an unshielded, geometrically coded two-core flat cable. The special geometry of these cables prevents incorrect contacting (reverse polarity protection).

Originally developed in the automotive sector, this bus system is very popular in the field of production automation and is standardized to ISO 11898.