The mobility transformation has come to a standstill. The reasons for this are high purchase prices, limited ranges, a lack of infrastructure and long charge times. A consortium of experts from GG Group, VOSS Automotive and Amphenol-Tuchel Electronics has now come a significant step closer to finding a solution for shorter charge times: The vehicle-side high-voltage charging harness includes the innovative Power2Flow® charging cable, the CHARGESOK® CCS2 charging socket, a battery connection tailored to the vehicle and a powerful thermal management system for efficient cooling of the components. Thanks to the integrated heat dissipation inside the charging system, the current load capacity can be increased by around 70 percent with a significantly reduced conductor cross-section. The goal: to reduce the charge time of cars to less than 5 minutes.

The challenge: Overheating of the charging harness

Until now, the individual drive system components in electric vehicles, such as the inverter, the electric motor or the HV battery, have been liquid-cooled. However, the electrical cables between the systems, as well as the charging cable between the battery pack and charging inlet, remain uncooled. This leads to major restrictions in terms of charge time, as the charging currents have to be regulated in such a way that there is no risk of overheating. Existing solutions work with a considerable increase in cross-section, for example in busbars - but the result is more weight and inflexible cables, which has a disadvantageous effect on processing and handling.

Three industry leaders have now joined forces and developed a solution for this central challenge of e-mobility in a short space of time through close cooperation between the experts. The result is a partnership that benefits from their wide-ranging experience and expertise in the automotive industry: with GG Group for technologically sophisticated cables and charging systems, VOSS Automotive for individual thermal management solutions and Amphenol for innovative high-current connectors and charging infrastructure.

The solution: integrated cooling for the charging cable and socket

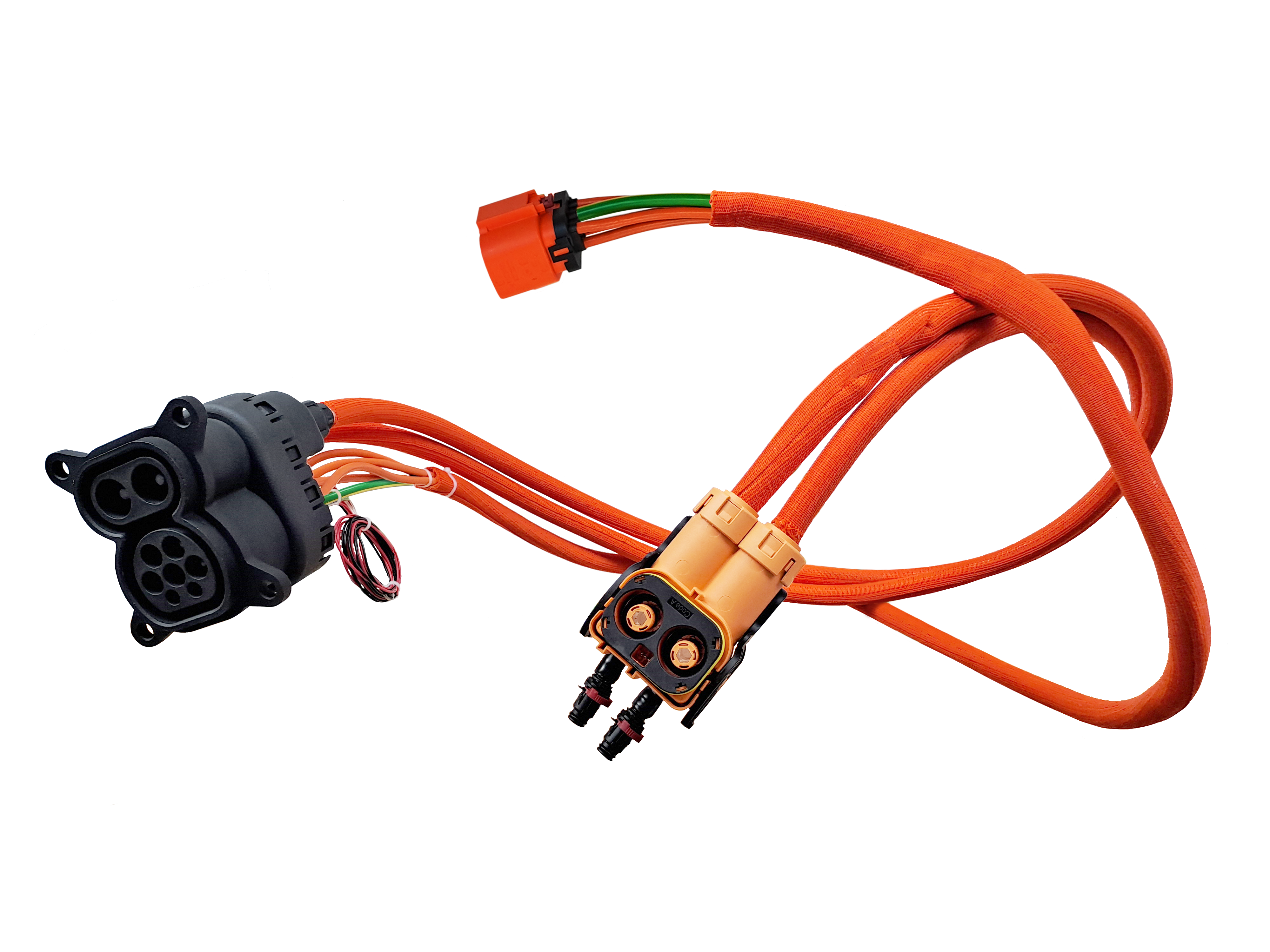

A central component of the innovative high-voltage charging system is the Power2Flow® charging harness from the GG Group. The high quality HV charging cable is encased in a robust insulation layer. The underlying stranded wire made of aluminum or optionally copper transmits the electrical power and ensures high flexibility and mobility of the cable thanks to a reduced cross-section. Inside this charging cable is the so-called VOSS polymer heat exchanger, a multi-layer plastic tube in combination with established VOSS quick connect systems. It transports the cooling medium and thus ensures sufficient cooling from the battery connection directly to the charging socket, where most of the heat is generated. The polymer heat exchanger is suitable for both cooling water and various immersion fluids and can therefore meet a wide range of requirements. The inner layer is electrically conductive, the outer layer is thermally highly conductive and provides electrical insulation. The high thermal conductivity of the soft outer layer enables very good heat transfer and thus a reduction in the cross-section of the electrical conductor. Within the system, the GG Group ensures the electrical properties of the charging harness with its experience in industrialization and contacting - together with the experts from VOSS also the fluidic requirements.

The interface to the charging infrastructure is via the performance-optimized CCS2 charging socket CHARGESOK® from Amphenol-Tuchel Electronics, which has an innovative direct cooling concept using the VOSS heat exchanger. A cooling medium actively circulates around the DC contact chambers. The socket is compatible with both conventional water-glycol mixtures and immersion fluids. This specific cooling leads to more efficient heat dissipation directly at the point of origin - i.e. where the current flow causes the highest thermal load.

The vision: charging in less than 5 minutes

The innovative high-voltage charging harness has the potential to significantly improve the performance of electric vehicles. Clearly higher currents over the entire charging process enable a considerably shorter charge time. This represents an important advance for the practical usability and everyday suitability of electric vehicles. The low weight, high flexibility of the cable and the resulting ease of installation also contribute significantly to this. The versatility of the system in terms of media flexibility allows easy integration into different cooling system architectures and increases the future viability of the solution with regard to new vehicle concepts and charging environments.